Valka has unveiled revolutionary frozen fish processing solutions that feature the technical precision and sophisticated design necessary to produce and ship high-quality products destined for the freezer aisle. The new Aligner Packing Robot and High-Speed Portion Grader for IQF products are part of a new line of frozen fish processing solutions enabling processors to maximise value and minimise waste.

The Aligner Packing Robot is set it apart from standard equipment in the frozen fish processing category because it applies a game theory algorithm based on the weight, length, or quality of each fish to determine the best solution, reducing overpack and minimal giveaway. It automatically grades, batches and packs unique quick-frozen (IQF) fillets with the unique capabilities to meet the most specific packing requirements. With a capacity of up to 80 frozen pieces per minute of fish ranging in size from 80 to 800 millimetres in length, the Aligner Packing Robot boasts a carousel car that gently handles products from the scale to the box. These remarkable features ensure premium product quality and significantly reduce waste.

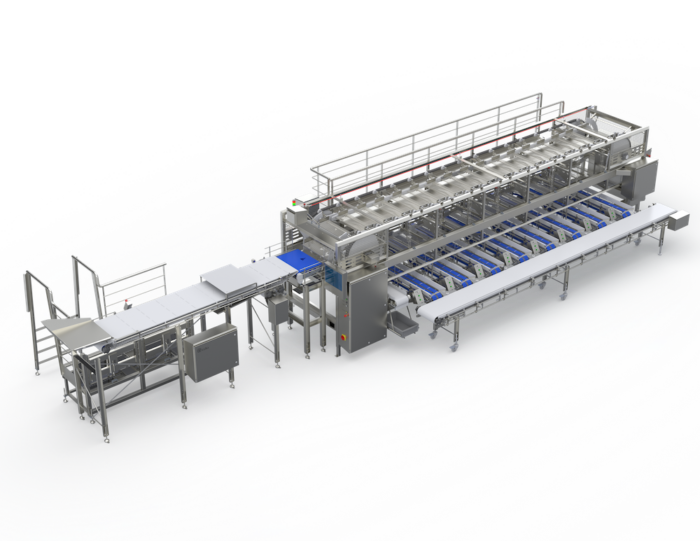

Customisable by design, Valka’s High-speed Portion Grader can be built with up to four lanes that simultaneously and automatically sort products based on weight and dimensions, and processors can choose whether they want it to with a fully-automated system or the traditional circular feed. Offering unparalleled per square meter throughput, the High-Speed Portion Grader allows for the better economisation of limited space in facilities. Boasting a soft dropping mechanism at each gate, the gentle touch technology allows products to flow smoothly into the buffer, keeping the frozen fish offerings untouched and efficiently packed in any size box.

Since debuting its water-jet cutting machine at Seafood Expo Global 2014 in Brussels, Belgium, Valka has been focused on increasing its processing presence worldwide. The company contracted with Båtsfjordbruket in September 2019 to provide two complete automated fillet processing lines for whitefish and salmon. It also contracted with Norway’s SalMar in March 2020 to give the seafood supplier with a state-of-the-art salmon grading and packing system. Learn more about Valka’s groundbreaking frozen fish processing solutions here.